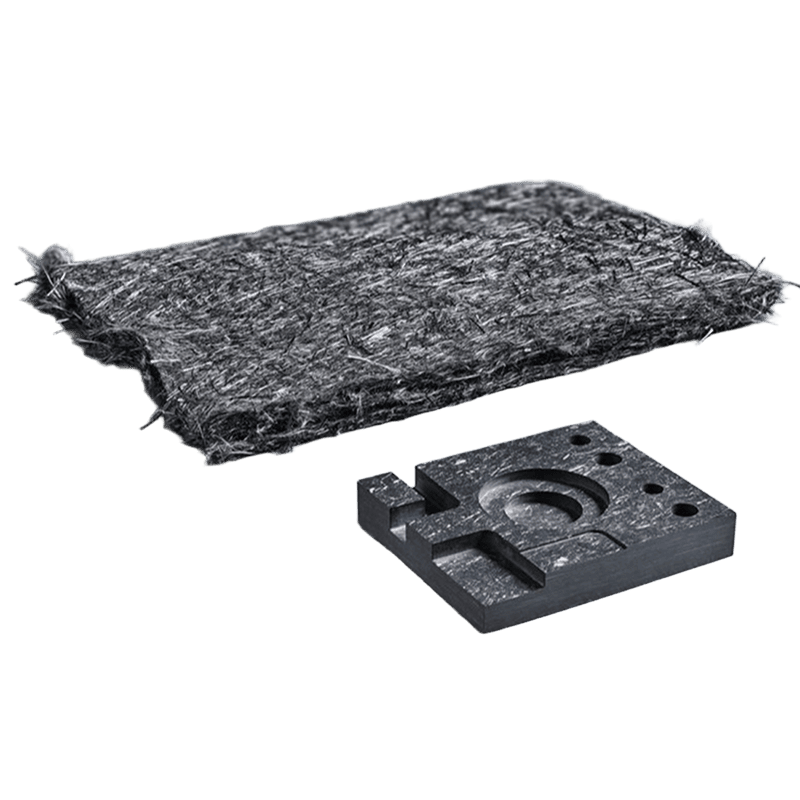

Chopped Carbon Fiber

Chopped carbon fiber is produced by cutting continuous carbon fiber filaments into short segments typically ranging from 3 to 50 millimeters. It is commonly blended with resin for use in compression molding, injection molding, and other processing methods. With excellent dispersion, it enhances the mechanical properties of the material while maintaining lightweight characteristics. Suitable for manufacturing complex-shaped parts, it features simple processing and high flexibility, making it a key raw material in composite manufacturing.

|

Carbon Content |

95% |

|

Tensle Strength |

3500mpa |

|

Tensile Moduous |

228gpa |

|

Density |

1.75g/cm³ |

|

Electrical Resistivity |

1.0-1.62cm |

|

Diameter Offiber |

7um |

|

Sectional Shape |

round |

|

Bulk Density |

0.4g/cm³ |

|

Standard Length |

1mm-100mm |

|

With Resin/withoutresin |

|

The corresponding specifications can be customized according to customers.

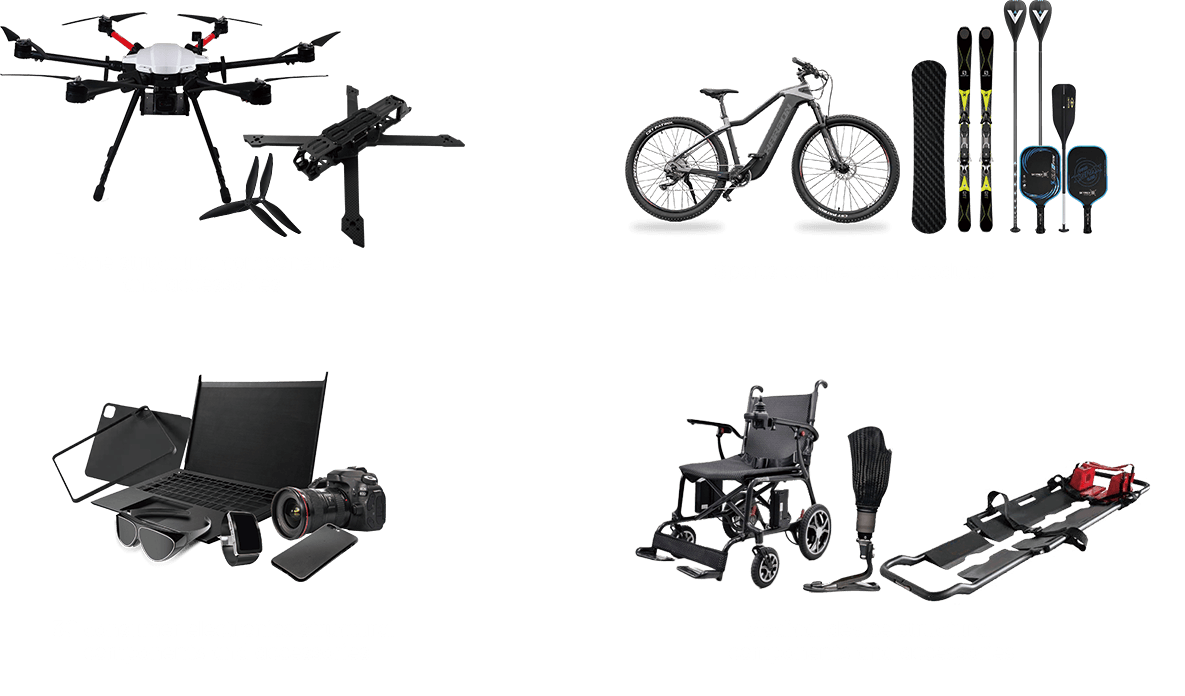

Carbon fiber Application areas

Carbon fiber composite materials have the advantages of high temperature resistance, corrosion resistance, friction resistance, tight weight, high strength and good toughness. Due to its outstanding performance advantages, it has been used in many fields, but its main application fields are: aerospace, automobile manufacturing, industrial applica- tions, sporting goods, etc. Carbon fiber is widely used, and carbon fiber materials will be used to replace traditional materials in key parts of many equipment.