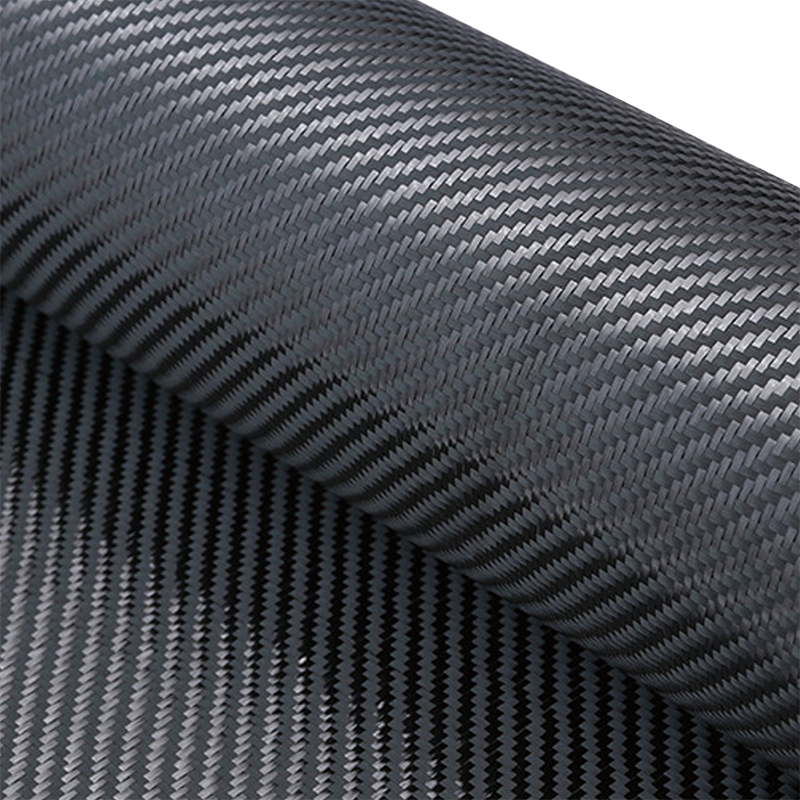

Woven Carbon Fiber Prepreg

Woven carbon fiber prepreg is made by impregnating carbon fiber fabrics—woven in specific patterns such as plain weave or twill—with resin. It offers high strength, lightweight properties, and multidirectional mechanical performance. The woven structure enhances resistance to delamination and impact, making it well-suited for components with complex geometries and multidirectional loading. It is widely used in aerospace, automotive, and marine industries for manufacturing high-performance composite parts through compression molding or autoclave processes.

Main Parameter

|

Type |

Yarm |

Weave |

Dry weight |

Total weight |

Resin content |

Width |

Thickness |

|

|

Warp |

weft |

|||||||

|

XX-1011 |

1K |

1K |

Plain |

120 |

205 |

40 |

1000 |

0.16 |

|

XX-1021 |

1K |

1K |

Twill |

120 |

205 |

40 |

1000 |

0.16 |

|

XX-3011 |

3K |

3K |

Plain |

200 |

330 |

40 |

1000 |

0.28 |

|

XX-3021 |

3K |

3K |

Twill |

200 |

330 |

40 |

1000 |

0.28 |

|

XX-3031 |

3K |

3K |

Football stripes |

240 |

405 |

40 |

1000 |

0.30 |

|

XX-6011 |

6K |

6K |

Plain |

320 |

530 |

40 |

1000 |

0.40 |

|

XX-6021 |

6K |

6K |

Twill |

320 |

530 |

40 |

1000 |

0.40 |

|

XX-6031 |

6K |

6K |

Satin |

400 |

665 |

40 |

1000 |

0.40 |

|

XX-7011 |

12K |

12K |

Plain |

400 |

670 |

40 |

1000 |

0.50 |

|

XX-7021 |

12K |

12K |

Twill |

480 |

800 |

40 |

1000 |

0.55 |

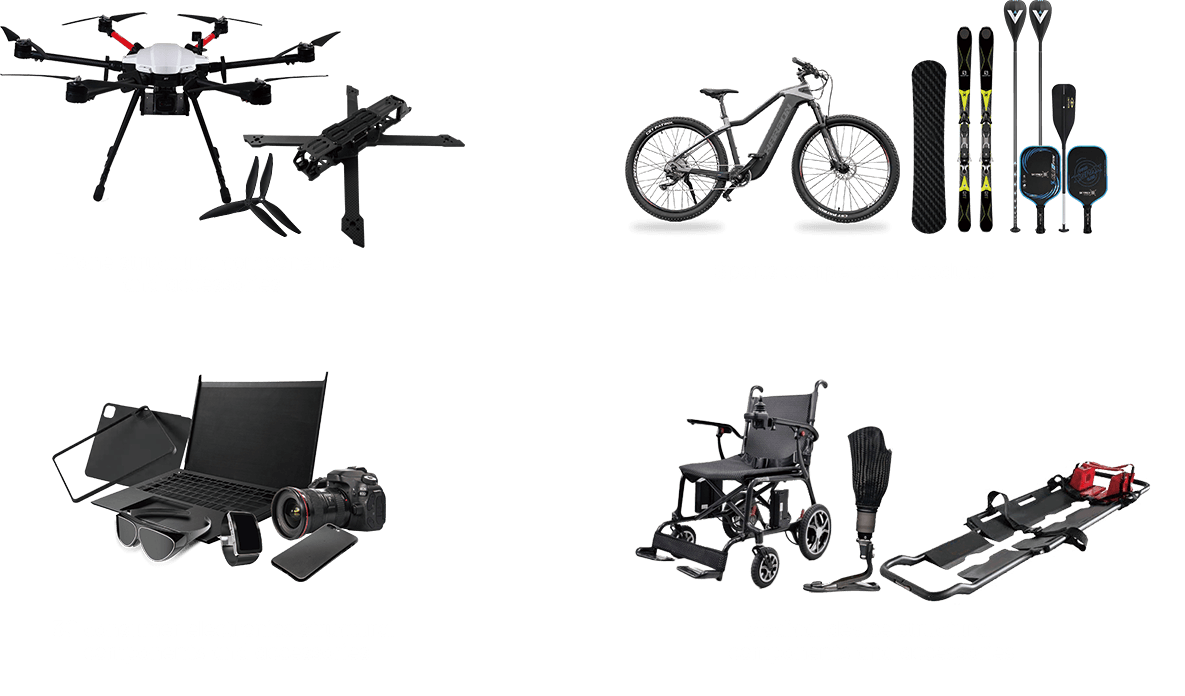

Carbon fiber Application areas

Carbon fiber composite materials have the advantages of high temperature resistance, corrosion resistance, friction resistance, tight weight, high strength and good toughness. Due to its outstanding performance advantages, it has been used in many fields, but its main application fields are: aerospace, automobile manufacturing, industrial applica- tions, sporting goods, etc. Carbon fiber is widely used, and carbon fiber materials will be used to replace traditional materials in key parts of many equipment.