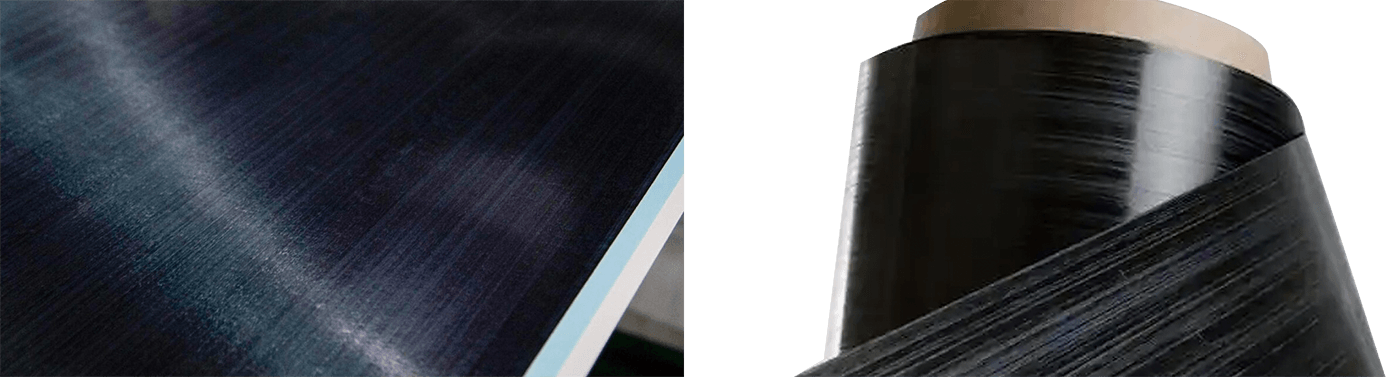

Unidirectional Carbon Fiber Prepreg

Unidirectional carbon fiber prepreg is made by impregnating aligned carbon fibers with resin. All fibers are oriented in the same direction, resulting in high specific strength, high specific modulus, and pronounced anisotropic properties. It exhibits excellent load-bearing performance along the fiber direction and is suitable for producing lightweight, high-performance composite components through autoclave or compression molding processes.

Storage Life of Carbon Fiber Prepreg

Under different temperature conditions, the shelf life of the carbon fiber prepreg is as follows:

At 22°C (room temperature): up to 1 month

At 0°C: up to 3 months

At -18°C (freezer storage): up to 6 months

Carbon Fiber Prepreg

The main products include:unidirectional carbon fiber prepreg (24T,30T,36T,40T),and carbon fiber woven prepreg (1К,3К,6К,12К),аll кіnds 0f hуЬrіd рrерrеg аnd sо оn.Unіdіrес- tionalfabric weight is from 30g/m2 to 600g/m2, the resin con- tent uniformity controlled within 0.5%.Weight of the fiber and the resin content can be produced according to customer requirements.

Storage Life of Carbon Fiber Prepreg

Under different temperature conditions, the shelf life of the carbon fiber prepreg is as follows:

At 22°C (room temperature): up to 1 month

At 0°C: up to 3 months

At -18°C (freezer storage): up to 6 months

Unidirectional Carbon Fiber Prepreg

Unidirectional carbon fiber prepreg is made by impregnating aligned carbon fibers with resin. All fibers are oriented in the same direction, resulting in high specific strength, high specific modulus, and pronounced anisotropic properties. It exhibits excellent load-bearing performance along the fiber direction and is suitable for producing lightweight, high-performance composite components through autoclave or compression molding processes.

Main Parameter

|

Type |

Dry weight |

Total weight |

Resin content |

Width |

Thickness |

|

xx-03000 |

30 |

76 |

55 |

1000 |

0.03 |

|

xx-05000 |

50 |

91 |

45 |

1000 |

0.06 |

|

XX-07500 |

75 |

121 |

38 |

1000 |

0.08 |

|

XX-10000 |

100 |

150 |

33 |

1000 |

0.10 |

|

XX-12500 |

125 |

187 |

33 |

1000 |

0.13 |

|

XX-15000 |

150 |

224 |

33 |

1000 |

0.15 |

|

XX-17500 |

175 |

261 |

33 |

1000 |

0.18 |

|

XX-20000 |

200 |

298 |

33 |

1000 |

0.20 |

|

XX-22500 |

225 |

337 |

33 |

1000 |

0.23 |

|

XX-25000 |

250 |

374 |

33 |

1000 |

0.25 |

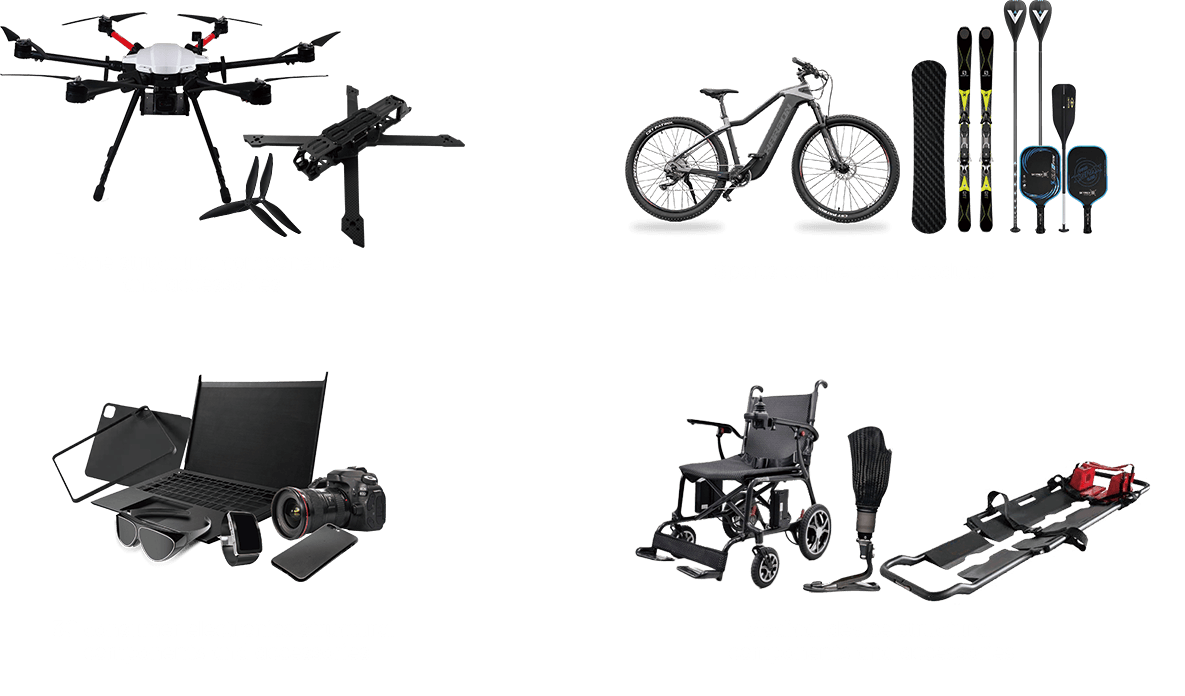

Carbon fiber Application areas

Carbon fiber composite materials have the advantages of high temperature resistance, corrosion resistance, friction resistance, tight weight, high strength and good toughness. Due to its outstanding performance advantages, it has been used in many fields, but its main application fields are: aerospace, automobile manufacturing, industrial applica- tions, sporting goods, etc. Carbon fiber is widely used, and carbon fiber materials will be used to replace traditional materials in key parts of many equipment.

Characteristics and applications of carbon fiber

|

Characteristic |

Application Areas |

|

High specific strength, high elasticity |

Aviation, aerospace, transportation, wind turbines, civil engineering, pumping rods and so on |

|

Fatigue resistance |

Plate spring, helicopter rotor, high-speed rotary body and so on |

|

Thermal stability |

Electronic equipment, precision machining equipment, satellite equipment, instruments, weapons and equipment |

|

Conductivity |

Electrodes, composite core wire, electromagnetic shield and so on |

|

Anti-vibration attenuation performance |

Machine arm, racket, fishing rod, golf pole and so on |

|

Chemical stability |

C / C composite materials, high pressure vessels, chemical equipment and so on |

|

Corrosion resistance |

Chemical equipment, electrode materials, marine pipelines, oil tanks, building reinforcement materials |

|

Lightweight |

Automotive, aerospace, sporting goods and so on |

|

Non-toxic biological toxicity |

Medical supplies and so on |